Awọn ọja

Sintetiki Diamond didan Micro Powder

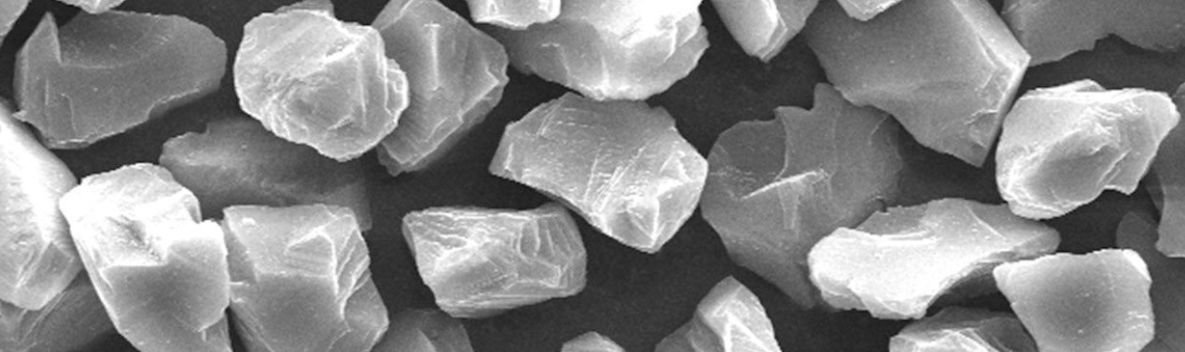

Monocrystalline Diamond Powder

Monocrystalline Diamond Powder jẹ iṣelọpọ lati awọn oka abrasive okuta iyebiye atọwọda nipasẹ ọna titẹ aimi, eyiti o fọ ati ti apẹrẹ ni lilo ilana pataki fun awọn ohun elo lile-lile. Awọn patikulu rẹ ṣe idaduro awọn ohun-ini kirisita ẹyọkan ti diamond gara kan.

| Sipesifikesonu | D50 (μm) | Sipesifikesonu | D50 (μm) |

| 0-0.05 | 0.05 | 5-10 | 6.5 |

| 0-0.08 | 0.08 | 6-12 | 8.5 |

| 0-0.1 | 0.1 | 8-12 | 10 |

| 0-0.25 | 0.2 | 8-16 | 12 |

| 0-0.5 | 0.3 | 10-20 | 15 |

| 0-1 | 0.5 | 15-25 | 18 |

| 0.5-1.5 | 0.8 | 20-30 | 22 |

| 0-2 | 1 | 20-40 | 26 |

| 1-2 | 1.4 | 30-40 | 30 |

| 1-3 | 1.8 | 40-60 | 40 |

| 2-4 | 2.5 | 50-70 | 50 |

| 3-6 | 3.5 | 60-80 | 60 |

| 4-8 | 5 |

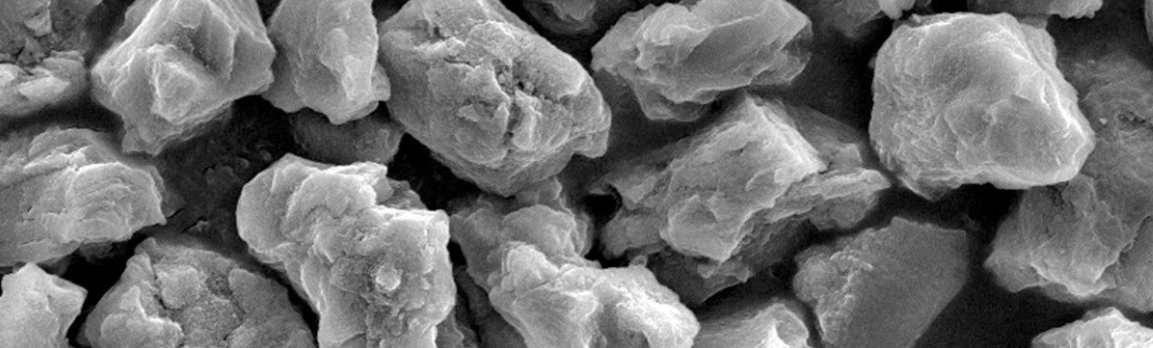

Polycrystalline Diamond lulú

Polycrystalline diamond lulú jẹ micron ati awọn patikulu polycrystalline sub-micron ti o jẹ ti awọn oka diamond pẹlu iwọn ila opin ti 5 ~ 10nm ti o ni asopọ nipasẹ awọn iwe ifowopamosi ti ko ni itọrẹ. Inu inu jẹ isotropic ati pe ko ni awọn ọkọ ofurufu cleavage. Ni giga toughness. Nitori awọn ohun-ini igbekale alailẹgbẹ rẹ, a lo nigbagbogbo fun lilọ ati didan awọn ohun elo semikondokito, awọn ohun elo amọ, ati bẹbẹ lọ.

Awọn iwọn to wa ti diamond micro lulú jẹ bi isalẹ:

Ọja Abuda

- Oversize patapata kuro

- PSD dín

-Iwa mimọ le de ipele ppm

-O wu dispersibility

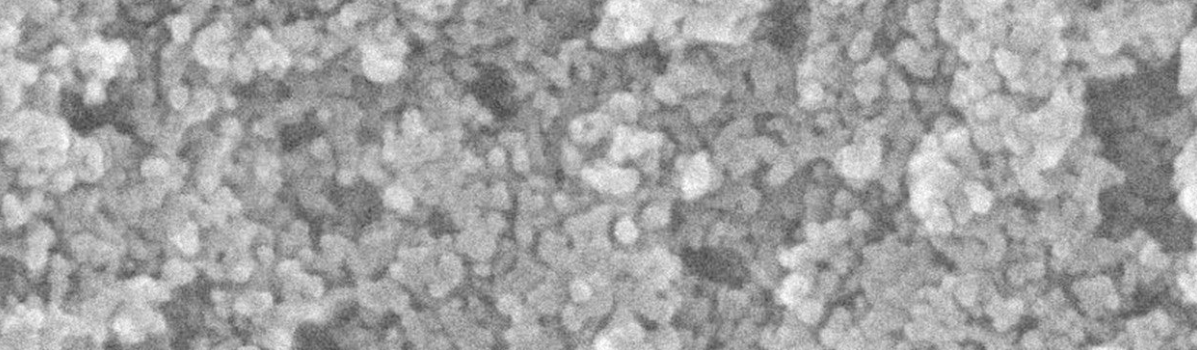

Nano Diamond Powder

Nano diamond lulú ti wa ni akoso pẹlu awọn kirisita kekere ti o wa ni isalẹ 20 nanometer, ipo ipadanu pataki ṣe agbejade diamond ti o ni apẹrẹ pẹlu ẹgbẹ iṣẹ ṣiṣe ọlọrọ lori dada, agbegbe dada kan pato ti pọ si nipasẹ aṣẹ kan ti titobi ni iyatọ pẹlu diamond monocrystalline. Ọja yii kii ṣe nikan ni lile lile ati awọn abuda lilọ ti diamond, ṣugbọn tun ni awọn abuda tuntun ti awọn ohun elo nanofunctional.

| Awọn iwọn | ND50 | ND80 | ND100 | ND120 | ND150 | ND200 | ND300 | ND500 | ND800 |

| D50(nm) | 45-55 | 75-85 | 90-110 | 110-130 | 140-160 | 180-220 | 280-320 | 450-550 | 750-850 |

Awọn abuda

Monocrystalline Diamond Powder Ohun elo

1. Dara fun orisirisi ga-konge electroplated Diamond onirin, electroplated Diamond lilọ wili, SiC gara Ige, ọbẹ, olekenka-tinrin ri abe, ati be be lo.

2. Ti o dara fun awọn iwe ohun ti o ni idapọmọra diamond, polycrystalline diamond ati awọn ọja ti o ni asopọ irin, awọn ọja amọpọ seramiki, awọn ọja diamond electroplated, bbl

3. Dara fun awọn irinṣẹ diamond electroplated, awọn kẹkẹ lilọ, bbl pataki ti a lo fun sisẹ awọn ohun elo lile ati brittle.

4. Ti o dara fun lilọ titọ ati didan ti awọn okuta iyebiye ti o ga julọ, awọn lẹnsi, awọn ohun elo metallographic, awọn paneli LCD, gilasi LCD, sapphire, quartz sheets, LED sapphire substrates, LCD gilasi, awọn ohun elo seramiki, bbl

Polycrystalline Diamond Powder Awọn ohun elo

1.Thin ati didan ti awọn wafers semikondokito, gẹgẹbi SiC wafer ati oniyebiye.

2.Surface polishing ti awọn orisirisi ohun elo seramiki

3.Surface polishing ti awọn ohun elo irin, gẹgẹbi irin alagbara, irin aluminiomu ati bẹbẹ lọ

Nano Diamond Powder Awọn ohun elo

1. Super itanran polishing. Irẹlẹ dada ti awọn iṣẹ iṣẹ didan le de ipele angstrom laisi awọn ika, eyiti o le ni itẹlọrun ibeere awọn ohun elo didan ti o nira julọ.

2. Nano diamond le ṣee lo bi awọn afikun epo lubricating. Ija edekoyede yoo yipada si ija yiyi, eyiti o le dinku olùsọdipúpọ edekoyede ati mu ilọsiwaju iṣẹ ikọlu naa pọ si ati tun fa igbesi aye iṣẹ naa pọ si.

3. Apapo plating ati spraying lori dada ti awọn orisirisi workpieces, mu yiya resistance, ipata resistance, ikolu toughness ati líle ti awọn workpieces 'dada.

4. Bi roba ati pilasitik additives, nano diamond le significantly mu awọn oniwe-yiya resistance, puncture resistance, fifẹ ohun ini ati ki o tun fa fifalẹ awọn ilana ti ogbo.

5. Ga ti nw nano Diamond yoo ko fa ti ibi ijusile, Nibayi o le wa ni o gbajumo ni lilo ni egbogi, ti ibi ati ohun ikunra aaye nitori ti awọn oniwe-nla kan pato dada agbegbe, lagbara adsorption o pọju.

Ibeere rẹ

Ti o ba ni ibeere eyikeyi. Jọwọ lero free lati kan si wa.